Cutters

Dull Blade: The most likely culprit is a dull blade. A dull blade can cause the top sheet to compress slightly as it's cut, resulting in a shorter final size compared to the bottom sheet. Solution: Regularly sharpen your guillotine cutter blade to ensure clean and consistent cuts.

Cutting Stack Height: If you're cutting a thick stack of paper, even with a sharp blade, there can be a slight difference in cut length between the top and bottom sheets. This is because the pressure of the blade compresses the stack slightly. Solution: Reduce the size of your cutting stack for more precise results, especially when using a potentially dull blade.

Triumph cutters are certified by Underwriters Laboratories (UL), a globally recognized safety certification organization. UL certification signifies that the cutters have undergone comprehensive testing and meet rigorous safety standards.

While certifications are important, Triumph cutters also boast exclusive SCS safety features* that further enhance user safety during operation. You can find more details about these features on the specific product pages or in the user manuals.

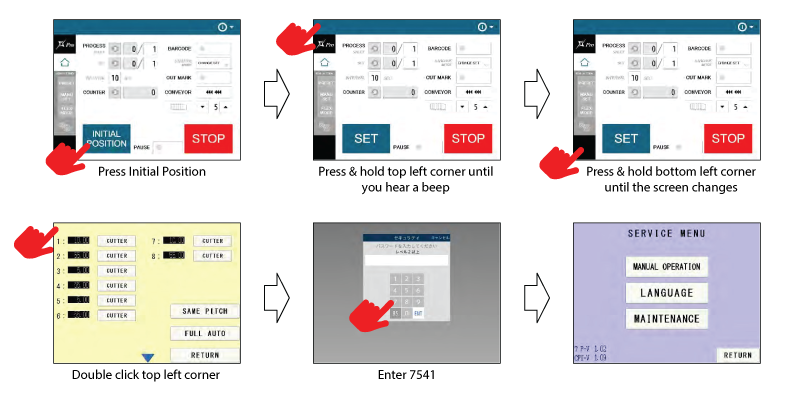

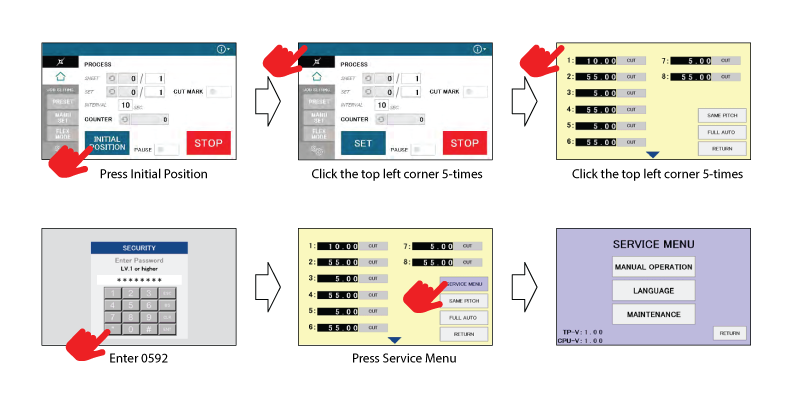

Gauge Correction: Followed the instructions and start reference run. When the reference is received, enter 10, 00 cm into the display and press "Start ". Insert paper and cut . Measure the paper and enter the correct dimensions into the display . Press save and the measurement is stored . Return to the normal display by pressing the return button.

MBM Website: Browse our selection of supplies and accessories on our website. Visit the "Accessories" section or search for your specific model to find compatible items.

Local Dealer: Many authorized MBM dealers carry replacement supplies. Our website offers a dealer locator tool to help you find a dealer near you.

Triumph Cutters & VRCut Ready Triumph Cutters: (Warning: use of non-approved cutting blades results in damage to the machine, thereby voiding warranty):

AeroCuts

Visit the Lytrod Store: https://lytrod.com/ Locate the Intellicut Success Plan that aligns with your needs (e.g., annual license, number of seats). Follow the on-screen instructions to complete the renewal process.

Visit Our Headquarters for a Demo (US Only): If you're located in the United States, you're welcome to visit our headquarters for a personalized demonstration of the AeroDieCut. Contact our sales team to schedule a convenient time.

Watch Video Demonstrations: We offer informative video demonstrations of the AeroDieCut on our website and YouTube channel https://www.youtube.com/@mbmcorp/videos.These videos showcase the machine's features, operation, and capabilities in detail.

Local Company Demonstrations: In some cases, a local company in your area might already own an AeroDieCut. We can try to connect you with them to see if they'd be willing to provide a demonstration.

Function:

Both machines offer similar core functionalities: slitting, cutting, and creasing.

Aerocut: Some Aerocut models may also include scoring and perforating capabilities. Feeding Mechanism: Aerocut: Utilizes an air suction system for feeding paper, which can offer better visibility of the paper flow. Other SCC: Employs a belt suction system, which might require more frequent cleaning of waste accumulating within the unit.

Ease of Use:

Aerocut: Features a touchscreen interface for easy operation and setup.

Other SCC: May require separate computer connection for some functionalities depending on the model.

Waste Management: The AeroCut allows for easier viewing of waste accumulation, whereas the waste bin in other SCCs might fill up unseen and require more frequent emptying.

Machine Footprint: It's advisable to compare the physical dimensions of each machine to ensure it fits comfortably in your workspace.

table { border-collapse: collapse; width: 100%; } th, td { text-align: left; padding: 8px 20px; /* Adjust padding as needed */ border: 1px solid black; } /* Center text in the first row */ th { text-align: center; }

| Features | AeroCutt | Other SCC |

|---|---|---|

| Function | Slit, Cut, Crease (optional: Score, Perforate) | Slit, Cut, Crease |

| Feeding Mechanism | Air Suction | Belt Suction |

| Interface | Touchscreen | May require separate computer (model dependent) |

| Waste Management | Easier visibility of waste accumulation | Waste bin may fill unseen |

| Machine Footprint | Check product specifications | Check product specifications |

Ultimately, the best choice depends on your specific needs. Consider factors like:

By carefully evaluating these factors and the information above, you can determine which machine best suits your requirements.

Software Updates: Regardless of your specific AeroCut model, you'll receive updates to ensure your machine runs the latest Intellicut software with bug fixes, new features, and compatibility enhancements.

Priority Technical Support: All program members receive priority access to MBM's technical support team for any questions or troubleshooting needs.

Training Resources: A library of training materials, including video tutorials and user guides, is available to all participants, regardless of the AeroCut model they own.

Folders

Uncreased Paper: The 1800S can handle paper stock up to a maximum weight of 216 gsm (equivalent to 80 lb. cover stock) for uncreased folds.

Creased Paper: If your paper has pre-existing creases, the 1800S can handle thicker stock up to 270 gsm (around 100 lb cover stock) for single folds only (half folds).

Important Note: When using heavier paper weights, especially with pre-existing creases, it's recommended to experiment with a small sample first to ensure the machine folds cleanly and without jamming.

The 208J is not recommended for cover stock, which is typically thicker and heavier than 120 gsm. The 208J may have difficulty feeding and folding slick or glossy paper stocks, especially those with high toner coverage. Avoid using 80 lb. gloss text paper for optimal performance.

With careful adjustment of the tension settings, the 508A can also handle: 80 lb. gloss stock with high toner coverage

The 408A is not recommended for cover stock, which is typically thicker and heavier than 120 gsm. The 408A may have difficulty feeding and folding slick or glossy paper stocks, especially those with high toner coverage. Avoid using 80 lb. gloss text paper for optimal performance.

MBM Website: Browse our selection of supplies and accessories on our website. Visit the "Accessories" section or search for your specific model to find compatible items.

Local Dealer: Many authorized MBM dealers carry replacement supplies. Our website offers a dealer locator tool to help you find a dealer near you.

Folders:

Trimmers

MBM Website: Browse our selection of supplies and accessories on our website. Visit the "Accessories" section or search for your specific model to find compatible items.

Local Dealer: Many authorized MBM dealers carry replacement supplies. Our website offers a dealer locator tool to help you find a dealer near you.

Trimmer: (Warning: use of non-approved cutting blades results in damage to the machine, thereby voiding warranty):

Creasers

Creaser:

Bookletmakers

MBM Website: Browse our selection of supplies and accessories on our website. Visit the "Accessories" section or search for your specific model to find compatible items.

Local Dealer: Many authorized MBM dealers carry replacement supplies. Our website offers a dealer locator tool to help you find a dealer near you.

Shredders

Destroyit paper shredders are certified by Underwriters Laboratories (UL), a globally recognized safety certification organization. UL certification signifies that the cutters have undergone comprehensive testing and meet rigorous safety standards.

Destroyit paper shredders also incorporate several built-in safeguards to minimize the risk of injury:

Patented Transparent Safety Shield: This shield acts as a physical barrier to protect fingers and hands from accidental contact with the cutting blades.

Automatic Cut-Off Functions: Shredding automatically stops when: The shred bag is full: This prevents overloading and potential jams, which could lead to injuries. The door is open: This safety feature ensures the shredder cannot operate when the door is ajar, preventing accidental contact with moving parts.

Integrated Photo Cell Technology: This feature automatically starts and stops shredding as you insert or remove paper. This eliminates the need to constantly hold down a switch, reducing the chance of operator error.

Destroyit shredders prioritize inherently safe design principles*. This means their features are built-in and function automatically, minimizing the need for user interaction that could potentially lead to accidents. For detailed information on specific models and their safety features, please refer to the product pages or user manuals.

MBM Website: Browse our selection of supplies and accessories on our website. Visit the "Accessories" section or search for your specific model to find compatible items.

Local Dealer: Many authorized MBM dealers carry replacement supplies. Our website offers a dealer locator tool to help you find a dealer near you.

Deskside & Centralized Office SC and CC Models:

High Capacity and SMC Models:

Air Purifiers

- M10 (particles with a diameter of 10 micrometers or smaller) – These can include dust, pollen, and mold spores.

- PM2.5 (particles with a diameter of 2.5 micrometers or smaller) – These fine particles are often found in smoke, vehicle emissions, and industrial pollutants.

- PM0.3 (particles with a diameter of 0.3 micrometers or smaller) – These ultrafine particles are commonly found in smoke and allergens.

- PM0.1 (particles with a diameter of 0.1 micrometers or smaller) – These are the smallest airborne particles, including viruses and combustion byproducts.

Software

MBM

Product Detail Page: Visit the product detail page for your specific product on our website (https://mbmcorp.com/). Most operator manuals are located directly on the product page for your convenience.

Resources Section: You can also find operator manuals in the Resources section of our website (https://mbmcorp.com/). Look for the "Resources" link, which is located on the top navigation bar.

If you're still having trouble finding the manual you need, feel free to contact our customer support team for assistance.

Product Detail Pages: Many of our product detail pages include videos directly embedded on the page. This allows you to easily see the product in action and learn about its features without leaving the website. Visit the product page you're interested in and look for a video section or player.

MBM YouTube Channel: We maintain a comprehensive YouTube channel (https://www.youtube.com/@mbmcorp/videos) featuring product videos, tutorials, and other informative content. Search the channel by product name or browse the playlists to find videos relevant to your interests.

We're continually adding new videos to our website and YouTube channel. If you can't find a video for a specific product, feel free to contact MBM customer support and they'll be happy to assist you.

Germany: Our IDEAL Air Purifiers, Destroyit Shredders, Triumph Paper Cutters, and some finishing equipment are manufactured in our state-of-the-art facility in Germany. This location leverages German engineering expertise to produce high-quality, precision machinery.

Japan: AeroCut and some finishing machines are built in Japan, renowned for its technological innovation and advanced manufacturing capabilities.

This global approach allows MBM to provide you with a diverse range of high-quality products, each built to meet specific performance requirements.

Inventory Level: If the items you order are in stock, your order has a good chance of shipping out the same business day, provided you place it by 2:00 PM Eastern Time (ET).

Order Processing: Orders are typically processed and shipped within approximately two business days.

Shipping Method: The chosen shipping method will also impact delivery time. Standard shipping times within the continental US typically range from 5 to 10 business days.

1. Account Verification: To access the dealer portal and service manuals, you must have a valid account set up with MBM. If you haven't already, go to the login page and to initiate the account creation process.

2. Logging In: Once you have an account, navigate to the MBM website. Locate the login link, which is on the top navigation bar. Enter your login credentials (username and password) and click "Log In".

3. Accessing Service Manuals: Upon successful login, you'll be directed to the secure dealer portal. Look for a section dedicated to "Service Manuals" or "Resources". Browse or search for the specific service manual you need based on the product model. You may be able to download the manual directly or find instructions for obtaining it.

MBM Website: Browse our selection of equipment and supplies directly on our website. This allows you to easily compare features, specifications, and pricing for different models.

Phone Sales: Contact MBM's inside sales team by calling our toll-free number. We can answer your questions, provide personalized recommendations, and process your order over the phone.

Authorized Dealers: MBM has a network of authorized dealers across many locations. You can find a dealer near you using the dealer locator tool on the MBM website. This option allows you to see the equipment in person, get hands-on experience, and potentially benefit from the dealer's expertise and service offerings.

Warranty/Service

- lifetime limited warranty on cutting shafts and wheels

- 3-year limited warranty on all other parts, excluding wearables

- 90-day limited warranty on labor or exchange at MBM’s discretion

- 1-year limited warranty on cutting shafts and wheels

- 1-year limited warranty on all other parts, excluding wearables

- 1-year limited warranty, excluding wearables

- 6-month limited warranty on pressure sealers, excluding wearables

- 1-year limited warranty, excluding wearables

- 1-year limited warranty, excluding wearables

- 1-year limited warranty on mechanical parts

- 90-day limited warranty on electrical and electronic

- 90-days limited warranty, excluding wearables