VRCut Ready Triumph 7260 Paper Cutter

Features

• Electric Paper Cutter

• Cutting Width: 28″

• Cutting Height: 3″ (with and without false clamp)

• Length Behind Blade: 28″

• Narrow Cut: 3/4″ (3 1/2″ with false clamp)

• Clamp Type: Adjustable Hydraulic

Product Details

• Item #: CU0494V

• Blade Material: German steel

• Horsepower: 2

• Electrical Requirements: 208/230 V. AC. 50/60 HZ, 3-Phase plug, 20-amp circuit breaker, L15-20R

• Dimensions (D x W x H): 60 1/2″ x 51 3/8″ x 52 1/2″ (63″ x 82 1/2″ with side tables)

• Shipping Weight: 1,534 lbs. (1,622 with side tables)

VRCut Brochure

VRCut Controller Hardware Kit

$ 35,266

Find DealerThe MBM Triumph 7260 28” programmable paper cutter offers outstanding precision and performance for high-volume cutting. Equipped with a hydraulic clamp and power back gauge, it ensures accurate, efficient cuts for various paper sizes. The intuitive touchpad control module simplifies programming and operation, enhancing productivity. With IR safety light beams on the front table, this cutter prioritizes user safety, preventing accidental injuries during operation. Perfect for offices, print shops, and commercial businesses, the Triumph 7260 paper cutter delivers reliable, consistent results, making it the ideal choice for companies seeking a powerful, safe, and efficient solution for all their paper-cutting needs.

• Comprehensive SCS safety package: patented easy cut electronic blade activation bars for true two-hand operation

• IR Light Beam Safety Curtain covers the work area to ensure the highest level of operator safety

• Safety cover on rear table

• Main switch and safety lock with key

• 24 volt controls (low voltage)

• Patented IDEAL safety drive

• Automatic blade return from every position

• Disc brake for instant blade stop

• Blade changing device covers cutting edge of blade

• Blade depth adjustment from outside of machine

• Blade and cutting stick can be changed without removing covers

• 28" programmable cutter with hydraulic clamp, power back gauge, 7" touchpad control module, and IR safety light beams on front table

• Hydraulic clamp drive

• Foot pedal for pre-clamping

• Electric back gauge drive with control module for easy programming

• Digital measurement display (cm or inches) with multilingual operator guidance, accurate to 1/10 mm or 1/100 inch

• Stores 99 programs with up to 99 steps in each (up to 15 repeat cuts can be integrated as a single step)

• Pre-programmed for standard paper sizes

• Memory keys for repeat cuts (manual) and quick setting of frequently needed measurements

• Automatic SET function for reference measurement and paper eject function with and without program mode

• Delete and insert mode for correcting and modifying programs

• Automatic correction in case of back gauge displacement

• Push buttons for fast back gauge movement (forward and reverse)

• Integrated calculator

• Self-diagnostic system with error indication on display

• Electric blade drive with solid steel carrier and adjustable guides

• Electronic back gauge control with variable speed control for manual back gauge setting

• Clamp pressure is fully adjustable between 550 and 4,400 psi

• False clamp plate with optical indicator

• Bright, LED optical cutting line

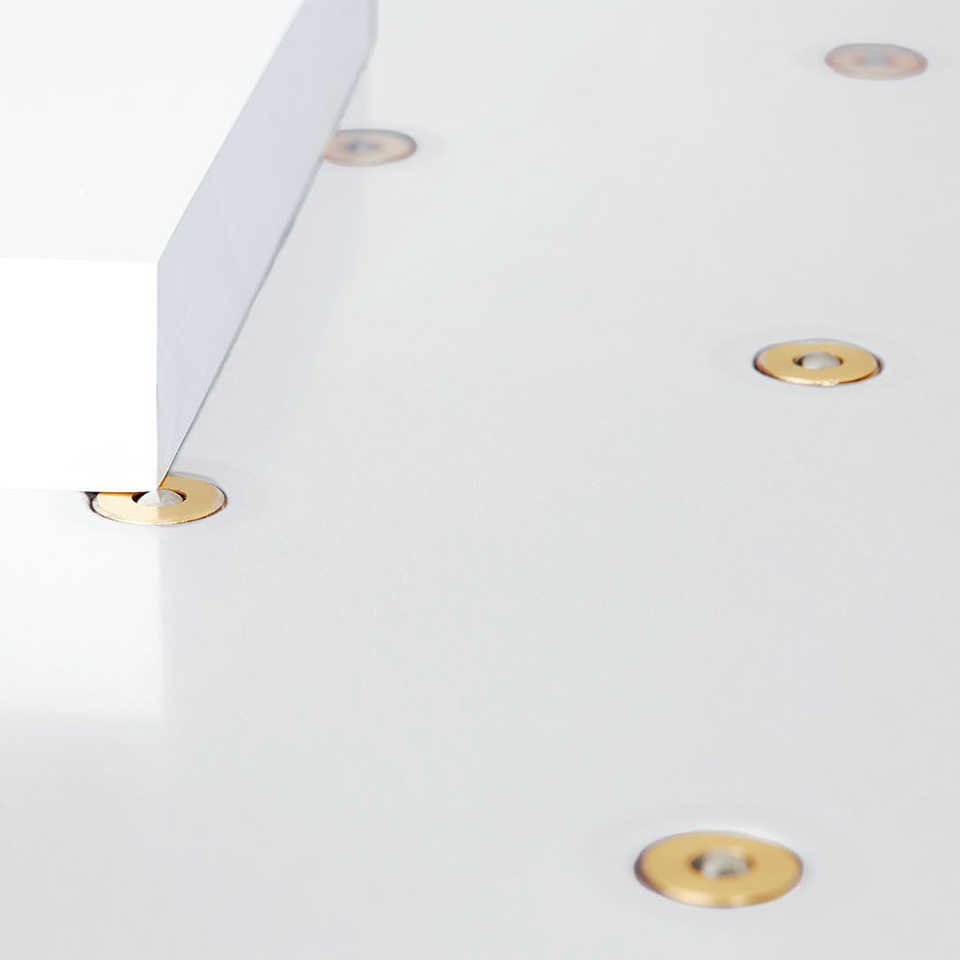

• Standard air tables (front and rear)

• High quality, German HSS blade

• Precision swing cut blade movement

• All-metal construction

• Includes easy-access tool holder and paper blocking tool

• Optional side tables increase work surface

• UL and C UL approved

• 1-year limited warranty, excluding wearables

• The use of a Phase converter is strictly prohibited. If used it voids warranty

• We do our best to get your products to you as quickly as possible

• The items ship directly from our warehouse and generally arrive within 5 to 10 business days

• In the event that any or all of your items require extra processing time, you will be notified via the contact information provided

• Shipping weight: 1,534 lbs. (1,622 with side tables)

• Ships via freight truck (large truck dock-to-dock or liftgate-to-ground delivery). White-Glove Service optional (White Glove Service is delivery, assembly, plus debris removal)

VRCut is a groundbreaking PC software solution designed to automate the cutting workflow by promoting an efficient and error-free cutting process from start to finish. VRCut intelligently bridges the gap between pre-press and the finishing process, allowing operators of any experience level the ability to cut with confidence on select Triumph cutters.

Two modules, one integrated workflow The VRCut solution consists of two independent modules that work together. The Impose module creates PDF documents formatted specifically to work with the VRCUT Controller module. The Controller module connects directly to the Triumph cutter moving the back gauge and visually guiding operators through the cutting sequence.

Frequently Bought Together…

Replacement Cutter Sticks for Triumph 7260 Paper Cutter AC0671

Replacement Cutter Sticks for Triumph 7260 Paper Cutter AC0671

Replacement Cutter Sticks for Triumph 7260 Paper Cutter AC0671

Replacement Cutter Knife for Triumph 7260 Paper Cutter AC0657

Replacement Cutter Knife for Triumph 7260 Paper Cutter AC0657

Replacement Cutter Knife for Triumph 7260 Paper Cutter AC0657